Strength and plasticity of metal at destruction by blow

One of perspective test methods of metal on blow is a method of the axial destruction by blow (ADB) [1].

ADB method is developed in JSC Russian Research Institute of the Tube and Pipe Industries and coordinated with Technical committee TC 145 "Steel products control methods" and allows to define plasticity of metal at destruction by blow and the impact strength of KCV, j/cm3.

At further development of a method results which allow to determine at test metal strength at destruction by blow are received.

It is possible to determine the strength at destruction by blow this method at a various temperature and speeds destructions of 5-10 m/s. and more. If strength is defined at speeds of 5-10 m/s. that for this purpose it is possible to use existing pendulum copra

Determination of strength of metal at big speeds of destruction requires creation of special pneumatic or stvolny systems that is real. The project of pneumatic system is developed in JSC Russian Research Institute of the Tube and Pipe Industries, and also the concept of stvolny system is developed.

It should be noted especially that at test by this method is used of a continuous cylindrical sample. That is, formation of cracks in metal at axial shock destruction happens in a sample on the basis of imperfections of a crystal lattice, local micro cracks in structure, places of a congestion of nonmetallic inclusions, etc. that approaches metal tests to real conditions of destruction.

Strength of metal is determined by the following scheme:

- work of destruction of a sample is fixed;

- conditional size destruction work is defined on unit of the deformed metal;

- the size of relative deformation in a zone of destruction is defined and further the size of conditional strength of metal is defined at shock destruction.

Everything is simple, but it is necessary to determine the linear size of a zone of destruction which wasn't defined earlier – there are difficulties. How many measurements – are so much sizes.

The author two options of measurements of a zone of the destruction, excluding influence on results of measurements of a human factor it was offer.

Now they are patented.

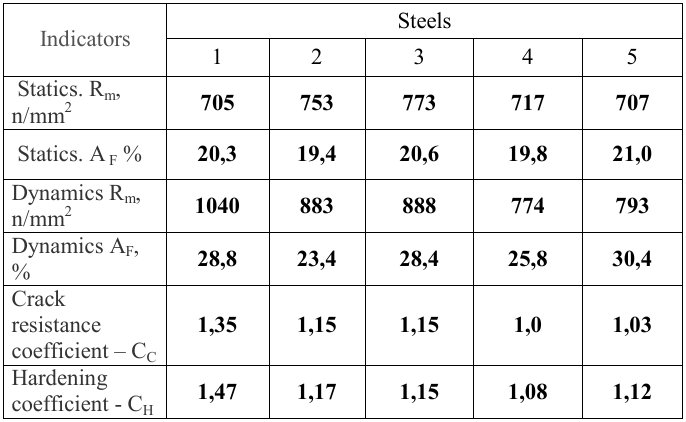

In the table No. 1a , results definitions of strength and plasticity of a row domestic and foreign steels a class of strength of CS 555 (C 65, X 80) are given at destruction with a speed of 5 m/s. and temperature 20 0C

It is special group low-carbonaceous, low-alloyed and fragmented fine-grained stale, treshchinostny pipes recommended for production for the main gas pipelines.

From the analysis of results of tests follows:

- strength af shock destruction steels significantly differs from 762 to 1060 N/mm2;

- hardening percent hesitates from 5 to 55 %;

- plasticity at shock destruction remains high and exceeds initial for 5-20%.

Knowing metal strength at shock (high-speed) destruction, it is possible to estimate work of the metal system working under a high pressure. For example, we will define operability of pipes of 1420х27,7 in size, the gas pipeline with pressure of 15 MPas made of metal of the table No. 1a.

For the answer to this question it is necessary to estimate the size of the maximum tension arising in a place of "failure" of the gas pipeline. The maximum tension, operating at the time of "failure", this district which size increases at the time of refusal in times. The formula of an assessment of tension is given in work [1,(3,2)]. For the chosen parameters its size is equal 770 N/mm2.

Sizes of coefficients of crack resistance are specified in the table No. 1 which are defined by the relation of strength of metal at destruction to breaking point size. Than more Ktr of subjects a high probability not crack developments after "failure" and vice versa.

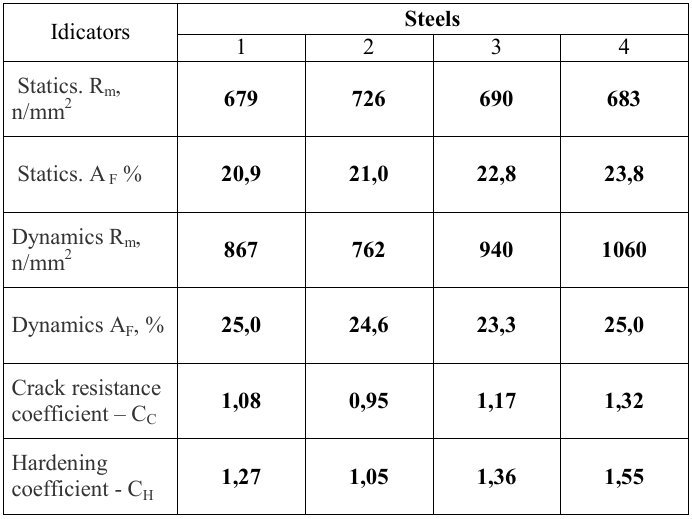

In the table No. 1b calculation Ktr is made for a pipe 1420х23,0 at P = 13 MPas, when σ = 800 N/mm2.

From the analysis of the given materials follows that for increase of productivity of selection steels for production of crackproof pipes, it is necessary to define strength properties of metal at shock destruction by the ADB method before polygon tests.

The results determine the impact characteristics of low-carbon and low-fine grain steels

Table number 1 (a)

Table number 1 (b)

Literature

1 . Yu.I.Blinov. Collection of articles "Method of axial destruction in blow. Crack resistance. Viscosity of metal" Chelyabinsk 2009-2012g